Yerin Kang, the founder of S.o.A, walks us through the 3-phase process used during the Metropolitan Small Manufacturers’ Support Center Design Competition, highlighting the importance of revealing the architecture’s attitude towards the city.

OUR PROCESS

We spend a lot of time understanding the background of the competition in the early stage. To this end, we analyze the competition guidelines and research on its social background. We try to figure out what socio-economic context we are dealing with and what role this building will play in this urban society.

We break down our process into pre-design, design and execution phases.

Pre-design phase:

- Understanding competition guidelines

We read the competition guidelines carefully. In particular, we discuss what the purpose of this competition is. It also constitutes a hierarchy of several guidelines for the competition. We discuss which item can have an absolute influence on our design and what guidelines should be considered first.

Metropolitan Small Manufacturers’ Support Center Design Competition (MMSC)’s case: The most important thing in this design guideline was how to define a ‘manufacturers’ support center’.

- Research on the socio-economic background of the competition

Especially in the case of public building competitions, the direction of city policy is often the background of the competition. We try to find out what kind of background city policy stands behind this competition. We study architectural types created under the same urban policy.

MMSC’s case: In this competition it was the Seoul Metropolitan Government’s support plan for urban manufacturing. The goal of this policy would become the goal of the design. Seoul’s shoe-making industry is concentrated in clusters of small sweatshops in the Seongsu-dong area, which is the site neighborhood. There is a spatial distribution of labor within the area: some are specialized in patterns, others in sewing, finishing, and sample making, etc. However, what is absent in the area is planning and designing. Only OEM manufacturing exists. Thus factory-owned original brands are also non-existent.

Decision making for design:

- To build a space structure where small manufacturers can create their own brands.

- We decided that the architecture itself should be able to reveal the brand identity. From the beginning, we tried to deviate from the typical building form.

- Analysis : asking questions and making design strategies

A few questions are created through analysis, and design strategies and ideas for the building are developed as answers to these questions.

Our questions in MMSC:

- There were numerous support programs for small factories, but to no avail. What were the problems?

- Which type of building can help and support small makers and factories?

- How to design not only a building scheme but also a new typology, which is necessary?

Design strategy in MMSC:

- Goal of our project: ‘Seongsu Silo’ to become a support center for small craft men so that they could be their own masters.

- Our definition of ‘Support center’: ‘Seongsu-Silo’ was designed to innovate a manufacturing area to enable master shoemakers to brand their hand-made products by integrating designing, manufacturing, marketing, distribution and consumption in one space.

- Design strategy: The production and consumption spaces were to be vertically interlinked, creating a compact geography of the commodity chain.

Design phase:

The design phase starts with sketching the core content of the proposal. When this sketch is complete, we discuss how to manipulate this sketch into 3-dimensional space.

- Main idea for brainstorming

MMSC’s case : a new type of factory. In order to integrate the processes of planning, designing, making, marketing and consuming, we placed all but the manufacturing area in front of the city. In addition, by arranging parts such as the meeting place and marketing space in a common space rather than inside a small factory,we have increased the importance of the service space.

The advantage of this layout was to separate the factory and service area and extend it easily when it is necessary to extend the building.

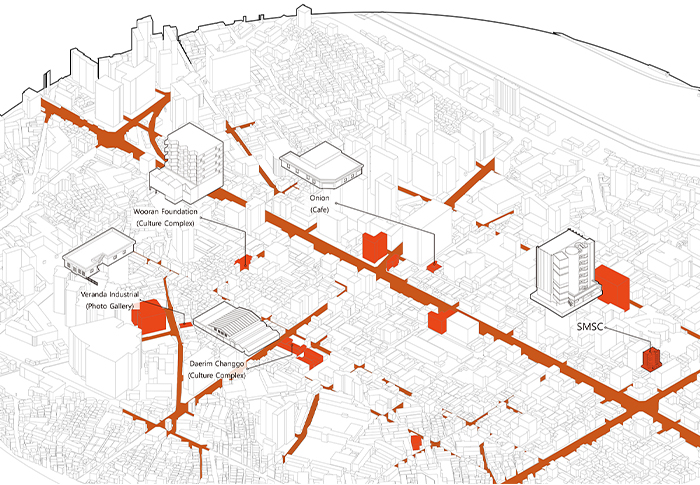

- Contextualizing an architecture to the city

Instead of being immersed in design proposals for a building, we zoom out again and study the real site where this building will be built. We look for the factors that can help the design of the building and, in order to make our building meaningful in the city, we look at the urban context.

MMSC’s case: The competition site, Seongsu-dong, used to be a factory area where only ‘production’ took place. But it has been transferred to a place where consumptions and culture platforms are added. Roads used for transportation in this area were gradually transferred into customers’ paths. This was an opportunity for manufacturers of handmade shoes to connect with consumers and markets.

Design factor from the site research:

- Lower part of a building opened to the public – based on this analysis, we proposed the low-rise façade of our building to open to the public area and the city. It was a comprehensive and three-dimensional arrangement of service areas that can complement and reinforce ‘production’

- Front cores – by arranging stairs and elevators at the front and direct access from the street, the city’s pedestrians could easily connect to the building.

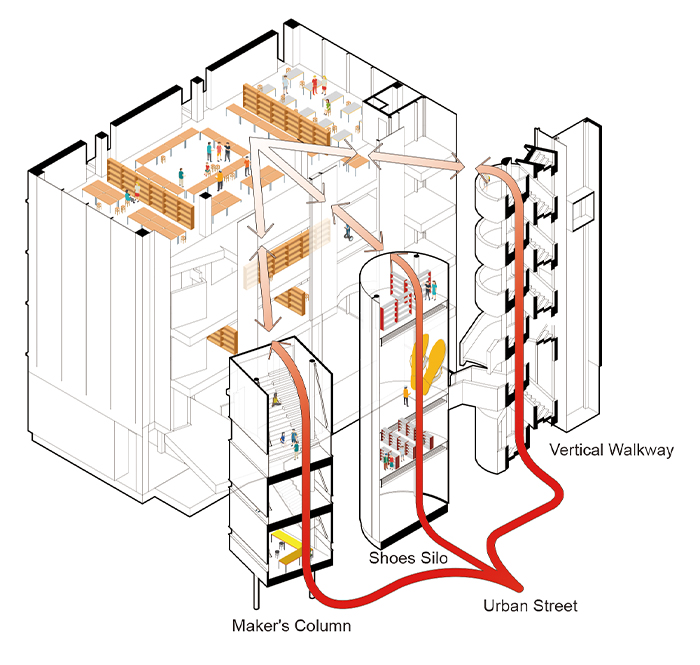

The core of the deployment was to place space elements on the front road that could result in an active interaction between people in the manufacturing industry’s branding process, such as planning, distribution, marketing, and exchange space. Workplaces and workspaces were planned to be variable, flexible and located at the rear of the site. Service elements, named Maker column, Shoes Silo, and Vertical Walkway, segmented the face of the building on a human scale on the front road, bringing pedestrians into the building.

- Visualizing a strategy: volume making to emphasize a manufacturing landscape

Various options studies are conducted on how to develop an initial idea into a three-dimensional space. In this case, both model making and 3d modeling are used. In the case of starting from a 3D drawing, it proceeds in the reverse direction. Study of plan or section in 3D modeling or model.

At this point, it is important to ensure that this process is not simply a process that crosses dimensions. The design strategy and implications for the way of form making should be articulated.

MMSC’s case: In the case of Seongsu Silo, we used “extrude’s strategy”, attempting to extricate ‘front side-service area’ and ‘back side-work area’ separately.

We did that for the following two reasons:

reason 1 – using the design language of ‘silos’. We hoped that the shape of the building would reflect the new floor plan and the traditional landscape of factory areas. The facade resembled a silo, which would act as a spatial branding tool for the factories in it.

reason 2 – to emphasize vertical connection to the city. To extricate each service is also a way to vertically connect architecture with the city. As a new type of factory tower, the Silo brings the production space and consumption space together in a 3-dimensional way, transforming into a compressed space of the geography of the commodity chain.

Small craftsmen’s workspaces are placed on each floor within an open plan. Three vertical ancillary spaces were placed in the front to support brand exhibitions, promotional spaces, stores, conference rooms, customized rooms, lecture rooms, etc. In between, the public space allowed the service area space of the front part to be opened to the outside independently. To make the service areas that new factories and support centers need to contain visually stand out, it was emphasized as an independent volume.

- Designing the characteristics of each area

After creating the overall volume and mass of the building, we have a stage of classifying and defining the characteristics of the detailed area. It is based on the meaning of the space program, and tries to secure the meaning in the whole area connected as one.

MMSC’s case: The front service silos were designed to look different. Since each service program is different, we wanted to find the geometry needed for it. If all silos were the same volume, it would have created a sense of incongruity in the alley:

“Maker’s Column”: A red brick was used to extend the urban landscape of the past, which was commonly used in factories around Seongsu-dong. By interpreting it as a horizontal window about 600 on the floor, it tried to emphasize the walking and shoes of people using the service space.

“Shoes Silo”: The front was designed in glass, but the back in brick, allowing it to be recognized as a visually open, independent space.

“Vertical Walkway”: The vocabulary of external evacuation stairs commonly found in Seongsu-dong was borrowed, but pedestrians can feel it as a vertical continuous walkway on urban streets.

Execution phase

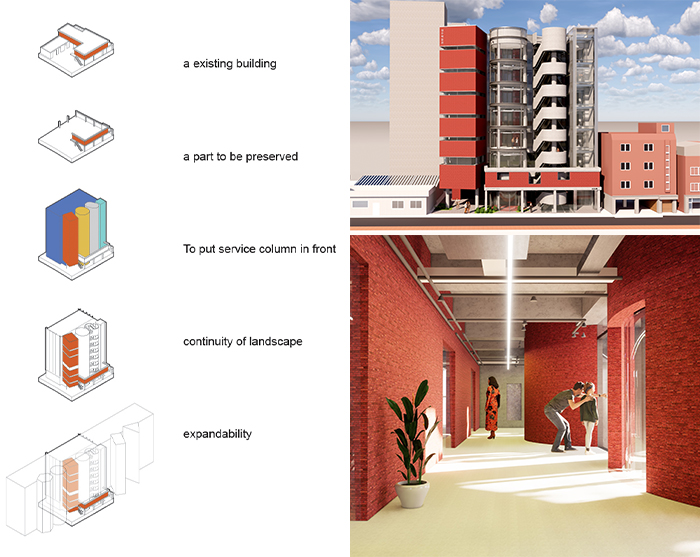

- Showing the process of renovation and expansion

In the case of a design competition, a process diagram is helpful to remodel and extend the existing building like MMSC. This diagram not only shows the order of the design, but also shows the attitude towards remodeling.

The title of each stage clearly reveals what is important in remodeling strategy and shows the process of building the content, not just the process of creating a volume.

MMSC’s case: The two-story elevation of the preserved building enclosing the service columns defined the service area independently. Between the pillars of the existing building, it was directly connected to the exhibition and multi-purpose space on the ground floor and the B1 floor. This gave consumers easy access to the service area of the upper floor as well as the lower floor of the building. This strategy lowers the psychological boundaries of visitors entering the building.

- Revealing the attitude of architecture towards the public.

As such, when a competition site is in the urban area, it is important to reveal the architecture’s attitude toward the city. This is because we are not only designing a stand-alone building, but also designing the relationship between the city and this building.

Since this part is difficult to explain, a perspective view from a pedestrian’s point of view is helpful. It is also necessary to refer to the city’s palette of materials and patterns for the selection and arrangement of materials.

MMSC’s case:

Lowering psychological boundaries. The construction strategy of the Small Manufacturers’ Support Center is basically expansion. The basic strategy of remodeling was to preserve the time of Seongsu-dong by leaving the 2nd floor façade of the existing building with the 2nd floor and the 1st floor columns, which embraced the newly created area and created a complex experience of entry. In particular, it created the identity of the building by establishing a relationship between the old and the new with a bundle of vertical elements on the front, named “Service Column”. It also served as a piloti or fence, naturally luring urban walking into the building and lowering the psychological boundaries of the entry process.

Continuity of industrial landscape. Factory buildings constructed with the minimum requirements for use have their own industrial aesthetics. The material palettes on the streets of Seongsu-dong are filled with common architectural languages based on ‘practical’ and ‘economy’. Most of the existing factories around Sungsu-dong are rahmen structures built by filling concrete frames with bricks, a typical type of construction in the area. Our building proposal used familiar materials to preserve the landscape of the street, but was intended to respect and develop the landscape of the place by changing its use. At this time, the preserved masonry wall of the existing building is also a fence and an open podium that binds the newly added Service Column.

- Zoom in distinctive design parts

In this state, we zoom in on the special parts and emphasize the design details as a perspective view collage or drawing can discover the meaning of design intention.

MMSC’s case:

Multi-purpose space in the lower part of the building. The ground floor was to be extended vertically to the second floor through the upper opening. Space was compartmentalized through a moving wall if necessary to form a flexible multi-purpose space. Floor materials inside and outside were made of the same material continuously and created a space open to the rear through the folding door. One could enter the first floor between the pillars of the existing building and directly access through the preserved stairs to the main office of MMSC on the second floor. The Shoe silo on the first and second floors was directly connected to the outside and an entry hall on the first floor, allowing visitors to enter the building through this space. On the second floor, where the MMSC was located, public space corridors served as mezzanines, and were connected vertically to the first floor.

System and organization of work production space. The balcony located inside the workspace and curtain wall outer walls located on both sides created a pleasant workspace. RC walls were secured to facilitate the installation of workstations and shelves. Service columns in public spaces strengthened the characteristics of public spaces by incorporating decorative bricks used externally into indoor materials.

A plan consisting of manufacturing, production space-exchange, network space-distribution, planning, and marketing space enabled a one-stop service. A casual meeting between small business owners and consumers could take place in a space in the front. The variable planar composition enabled reaction by organically transforming to suit the environment of various events and occupied spaces. In addition, the service space placed towards the road allowed the workspace to be freely extended from side to side.

For early small businesses, growth may increase the required space in a short period of time. Due to the continuous plan independent of the service area, the layout of the work space is easily adjustable. Only corridors could be blocked, and partitions can be positioned to the required area. Flexibility to expand space was provided as small businesses grew.

Yerin Kang

is an architect, professor and the founder and principal of Architectural Studio SoA (Society of Architecture). Based in Seoul, she also gained experience in Rotterdam.

She was awarded in ‘2015 Young Architects Project’ and nominated for the AR Emerging Architecture 2016 Finalists. In the same year, she won the Kim Swoo Geun Preview Award.

She participated in several exhibitions like Gwangju Design Biennale (2011), Italy MAXXI Exhibition (2012), APMAP Jeju Exhibition (2014), Young Architect Award Exhibition (2015) and was in charge of curating Producing City of ‘Seoul Biennale of Architecture and Urbanism’.

Her key projects include the Rabbit, Roof Sentiment, Yoonseul, Jeju Sayou: Living and Thinking in Architecture, Paju Book City Studio M, Space So which have been introduced in various international publications.

If you would like to ready more case studies like the one above please check our annual publication